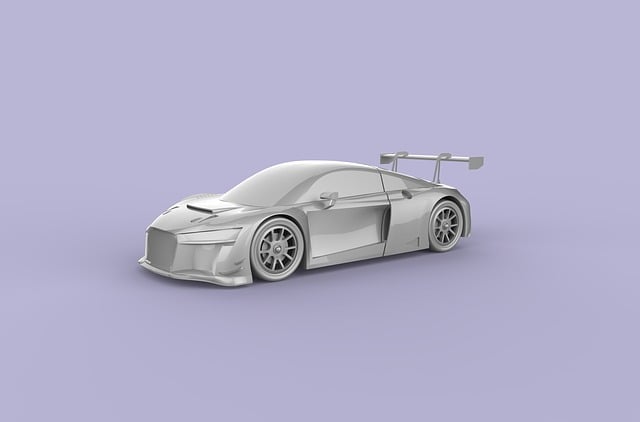

Body panel insulation (BPI) is a critical component in modern vehicles, enhancing safety and passenger comfort through energy absorption and noise reduction. It ensures structural integrity after collisions, maintains exterior aesthetics, and contributes to improved fuel efficiency. As a game-changer, BPI seamlessly integrates with collision repair services, offering both practical benefits and aesthetic preservation. Quality standards for BPI are stringent, with Original Equipment Manufacturer (OEM) guidelines ensuring structural integrity through rigorous testing. Installation involves meticulous surface preparation, precise cutting, and secure attachment using recommended adhesives and fasteners. For vehicle restoration projects, careful alignment maintains original aesthetics, exceeding OEM standards for a safe, quiet, and long-lasting ride, crucial for enthusiasts in car repair and restoration.

Body panel insulation is a game-changer in automotive manufacturing, enhancing energy efficiency and passenger comfort. This essential component plays a vital role in reducing weight, improving fuel economy, and minimizing noise levels. In this article, we’ll explore the significance of body panel insulation, delving into how it meets Original Equipment Manufacturer (OEM) quality standards. From understanding its critical functions to installation techniques, discover the process behind ensuring superior vehicle performance.

- Understanding Body Panel Insulation: Its Role and Benefits

- Ensuring Quality: Meeting OEM Standards

- The Process: Installation Techniques and Best Practices

Understanding Body Panel Insulation: Its Role and Benefits

Body panel insulation is a crucial component in modern vehicle construction, playing a vital role in both structural integrity and passenger comfort. It acts as a protective barrier, absorbing impact energy during collisions and minimizing noise and vibration, enhancing the overall driving experience. By effectively insulating the body panels, vehicles can maintain their structural integrity even after undergoing frame straightening or collision repair procedures at collision centers.

This technology offers numerous benefits beyond just safety and comfort. Proper insulation ensures that the vehicle’s exterior panels remain in pristine condition, preserving its aesthetic appeal and resale value. Moreover, it contributes to improved fuel efficiency by reducing heat transfer between the interior and exterior, thereby enhancing the energy efficiency of the vehicle. Understanding these advantages makes body panel insulation a game-changer in the automotive industry, especially when considering the seamless integration offered with collision repair services for damaged vehicles.

Ensuring Quality: Meeting OEM Standards

In the automotive industry, maintaining quality is paramount, especially when it comes to components like body panel insulation. To ensure safety and structural integrity, original equipment manufacturer (OEM) standards must be met or exceeded. This involves rigorous testing and adherence to strict guidelines throughout the production process. When it comes to body panel insulation, every detail matters—from material composition to installation precision.

OEM standards are designed to ensure that auto body repair, vehicle restoration, and automotive collision repair processes yield high-quality results. By adhering to these standards, manufacturers can guarantee that replacement panels not only match the original equipment in terms of performance but also contribute to the overall safety and reliability of the vehicle. This commitment to quality is what drives the industry forward, ensuring that every vehicle on the road meets the highest standards of safety and durability.

The Process: Installation Techniques and Best Practices

The process of installing body panel insulation involves careful preparation and precise techniques to ensure optimal results that meet OEM quality standards. First, the surface must be thoroughly cleaned and free from any contaminants or old insulation remnants. This step is crucial for achieving a seamless fit and long-lasting durability. Professionals often use specialized cleaners and sandpaper to create a smooth, even base. Once ready, the new body panel insulation is cut to size using accurate templates, tailored specifically for each vehicle model. This precision ensures it fits perfectly without any gaps or overlaps.

During installation, best practices include utilizing adhesive bonders recommended by manufacturers for optimal adhesion. The insulation is then securely attached, often with a combination of mechanical fasteners and adhesive, creating a robust, rigid structure. In the case of extensive damage or vehicle restoration projects, where body panel replacement is involved, careful alignment and panel gap adjustments are essential to maintain the vehicle’s original aesthetics. This meticulous approach, when combined with high-quality materials, results in a restored car or truck that not only meets but exceeds OEM standards, ensuring a safe, quiet, and durable ride for years to come—perfect for those passionate about car paint repair, scratch repair, or any enthusiast seeking top-tier vehicle restoration.

Body panel insulation is not just an add-on feature, but a crucial component for enhancing vehicle performance and comfort. By ensuring it meets Original Equipment Manufacturer (OEM) quality standards, automotive manufacturers can achieve superior thermal management, reduced noise levels, and improved fuel efficiency. Understanding the role of body panel insulation and adhering to best practices during installation are essential steps in achieving these goals, ultimately contributing to a more enjoyable driving experience for folks across the globe.